Why Safety Carpets Are Essential in Factories

Safety carpets are vital in preventing slips, trips, and falls, which are some of the most prevalent workplace incidents in factories. According to the National Safety Council, these accidents account for over 25% of reported workplace incidents. Safety carpets can significantly reduce such risks by providing a more stable and secure walking surface in high-risk areas prone to spills, wet conditions, or uneven flooring. For instance, they are often used near entrances and areas where water flow may occur, effectively absorbing liquids and minimizing hazards.

Moreover, by mitigating these risks, safety carpets not only enhance worker safety but also boost productivity. When employees feel secure in their environment, they can focus better on their tasks, culminating in fewer accidents and less work disruption. This sense of security unlocks confidence in the workplace, fostering a positive culture that aligns with businesses' safety priorities. Additionally, preventing injuries leads to fewer compensation claims and reduced downtime, ultimately benefiting the company's bottom line. In a landscape where operational efficiency is paramount, the importance of safety carpets for factories cannot be overstated.

Key Features of Effective Safety Carpets

Durability and Longevity

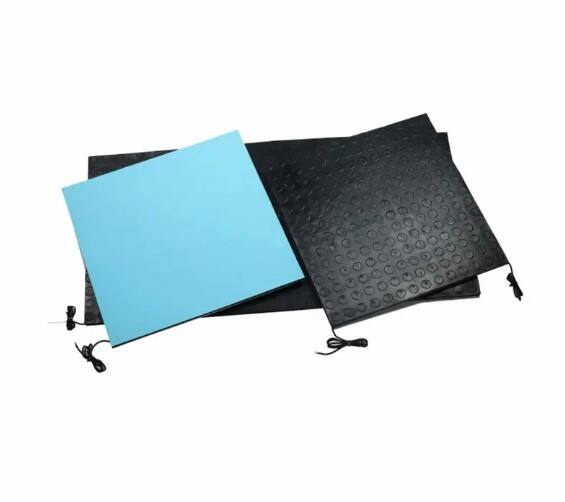

Quality safety carpets are crafted from sturdy materials like rubber or vinyl, designed to withstand the heavy foot traffic typical in factory settings. This robustness results in less frequent replacements, which is a significant cost-saving factor for industries. Investing in durable safety carpets pays off in the long run, as these high-quality options are resistant to wear and tear, ensuring they last for several years despite the harsh industrial environment.

Slip-Resistant Properties

The slip-resistant qualities of safety carpets are critical in preventing workplace accidents. Safety carpets are engineered with textured surfaces that provide a firm grip, drastically reducing the likelihood of slips, especially in areas prone to wet or oily conditions. Independent testing of these carpets’ slip resistance ratings ensures compliance with safety regulations, instilling confidence in their effectiveness and boosting their credibility as a safety solution.

Easy Maintenance and Cleaning

Ease of maintenance is a crucial aspect of effective safety carpets, facilitating hygiene in busy factory settings while minimizing operational downtime. Many safety carpets are designed to resist stains and can be cleaned effortlessly with basic cleaning supplies. This practicality makes them an ideal choice for factories, ensuring they remain hygienic and functional without requiring extensive or frequent clean-up efforts.

The Role of Safety Carpets in Compliance

Meeting OSHA Standards

Safety carpets play a crucial role in helping companies adhere to OSHA standards, which mandate the maintenance of a safe working environment. These standards are not just guidelines but legal requirements focused on minimizing workplace hazards. By incorporating safety carpets designed to enhance traction and reduce slip-related incidents, companies can meet these OSHA requirements efficiently. Compliance not only safeguards workers but also shields businesses from fines and legal repercussions associated with non-compliance. Ensuring that your workplace complies with OSHA regulations is vital for both operational integrity and employee safety.

Reducing Workplace Liability

Deploying safety carpets can significantly reduce the liability risks associated with workplace injuries. They provide an effective layer of protection that can lower the probability of slips, trips, and falls—a common cause of workplace accidents. According to a study by Liberty Mutual Insurance, such incidents cost businesses billions annually due to compensation claims and workdays lost. By prioritizing the installation of safety carpets, companies can potentially decrease insurance costs and lessen the likelihood of facing lawsuits related to workplace accidents. Safety initiatives like the employment of effective safety carpets go a long way in fostering a safer work environment and reducing overall liability.

Benefits of Safety Carpets Beyond Safety

Improving Workplace Aesthetics

Safety carpets are not just functional; they also play a crucial role in enhancing workplace aesthetics. Available in a wide range of designs and colors, these carpets can transform a mundane work environment into a visually appealing space. This transformation not only boosts employee morale but also contributes positively to the overall company image. An attractive workplace can be a key factor in staff retention and satisfaction, making employees feel proud to be part of a well-maintained, visually welcoming environment.

Reducing Fatigue and Strain

The cushioning properties of safety carpets are instrumental in reducing employee fatigue and strain. These carpets are particularly beneficial for employees who spend prolonged periods standing, as they provide a comfortable underfoot experience. Research consistently indicates that appropriate flooring solutions can significantly minimize discomfort and physical strain in industrial settings. By reducing fatigue, safety carpets help maintain productivity levels and protect workers' health, contributing to a healthier, more efficient workplace.

Choosing the Right Safety Carpets for Your Factory

Assessing Factory Needs

Selecting the right safety carpets begins with a thorough assessment of specific factory conditions. Factors such as traffic levels, types of machinery, and the presence of liquids or chemicals all significantly influence the choice of safety carpets. Conducting a needs assessment is crucial to ensure the chosen carpet meets all functionality requirements, including slip resistance and durability. It helps identify the precise features needed to enhance safety within the factory environment, optimizing protection against slips, trips, and falls.

Comparing Materials and Designs

A variety of materials are available for safety carpets, and choosing the right one requires careful comparison. Options like rubber, vinyl, and carpet tiles each offer distinct advantages depending on the factory's environment. Cost, maintenance requirements, and environmental impact are critical factors to consider during this process. Businesses need to weigh the benefits of each material against their specific needs, ensuring that the selected safety carpet not only fulfills safety requirements but also aligns with budgetary and ecological considerations.

FAQ Section

What are safety carpets?

Safety carpets are specially designed carpets used in industrial settings to provide a slip-resistant surface, reduce accidents, and enhance worker safety in areas prone to spills or uneven surfaces.

Why are safety carpets important in factories?

Safety carpets are crucial in factories as they prevent slips, trips, and falls, which are common workplace incidents. They also enhance productivity by creating a secure work environment and reducing the risk of injuries, compensation claims, and downtime.

How do safety carpets help in compliance with OSHA standards?

Safety carpets help companies adhere to OSHA standards by providing a safe working environment that decreases the likelihood of slip-related incidents, thereby meeting legal safety requirements and avoiding fines and legal issues.

What materials are used in safety carpets?

Safety carpets are commonly made from durable materials like rubber, vinyl, and specialized textiles that offer slip-resistant properties, durability, and ease of maintenance.

Can safety carpets enhance the aesthetics of a workplace?

Yes, safety carpets come in various designs and colors, allowing them to improve workplace aesthetics, boost employee morale, and contribute positively to the overall company image.